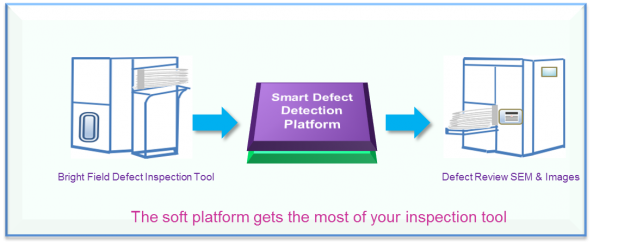

Intelligent Defect Detection Soft Platform – Based on Optical Inspection Technology

In semiconductor manufacturing processes, how to enhance the capability & efficiency of wafer defect inspection and then to increase total production yield rate should be the number one issue for all wafer manufacturers.

Based on optical inspection technology, we are proud to provide you with a series of well proven and advanced solutions to help you get the most of your existing inspection equipment. Our solutions are fully commercial available with friendly GUI to operation. Also, without using or interfering your GDS database, you may keep customers' data highly confidential.

To meet the trend of industry 4.0 and smart manufacturing, our solutions are perfect for all advanced wafer manufacturing processes.(e.g. 40nm, 28nm, 16nm, 14nm, 10nm, 7nm processes) 。

For further details or product demo/evaluation request, you are very welcome to contact us at:

support@aoelab.com.tw

Based on optical inspection technology, we are proud to provide you with a series of well proven and advanced solutions to help you get the most of your existing inspection equipment. Our solutions are fully commercial available with friendly GUI to operation. Also, without using or interfering your GDS database, you may keep customers' data highly confidential.

To meet the trend of industry 4.0 and smart manufacturing, our solutions are perfect for all advanced wafer manufacturing processes.(e.g. 40nm, 28nm, 16nm, 14nm, 10nm, 7nm processes) 。

For further details or product demo/evaluation request, you are very welcome to contact us at:

support@aoelab.com.tw

| Product | Description |

| Random Defect Inspection Platform A - To classify defect identity |

Auto Defect Classification Soft Platform The world’s leading random defect solution which predicts non-killer defects with more than 99.9% accuracy before SEM images’ shot. Screen non-killer defects has proven the catch of true failure random defect multiple times better than competitors’ in a 28nm Semiconductor Fab. |

| Random Defect Inspection Platform B - To select defect sample |

Auto Defect Sample Soft Platform By picking defect samples from the killer defects group using killer defect index (KDI) that targets true failure random defects. |

| Systematic Defect Inspection Platform - To catch weak patterns |

Weak Pattern Group and Sample Soft Platform By catching the Systematic defect patterns with both basic and advanced pattern grouping methods as well as smart GUI design intelligently. Weak pattern library help users manage systematic defects’ patterns much more efficiently. |

| Automatic Solution - The automation process between Defect Inspection and Review SEM & Image |

To trigger new defect job. To execute defect job. To upload defect results to server. To save tremendous amount of time cost |